... didn't happen today as planned, because FedEx didn't deliver our next batch of fershluginer parts on time. Instead, we had a shop cleanup and rearrange day, and I cleaned out my truck so my mother could take it to an Occasion tomorrow without being embarrassed at the state of it. None of that is really worth taking a bunch of photos and writing it up, but here's something I wanted to show you from before:

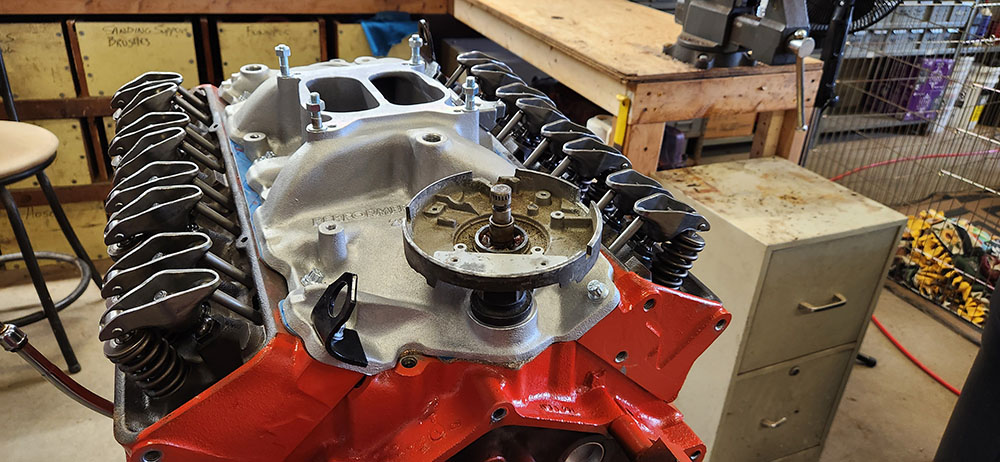

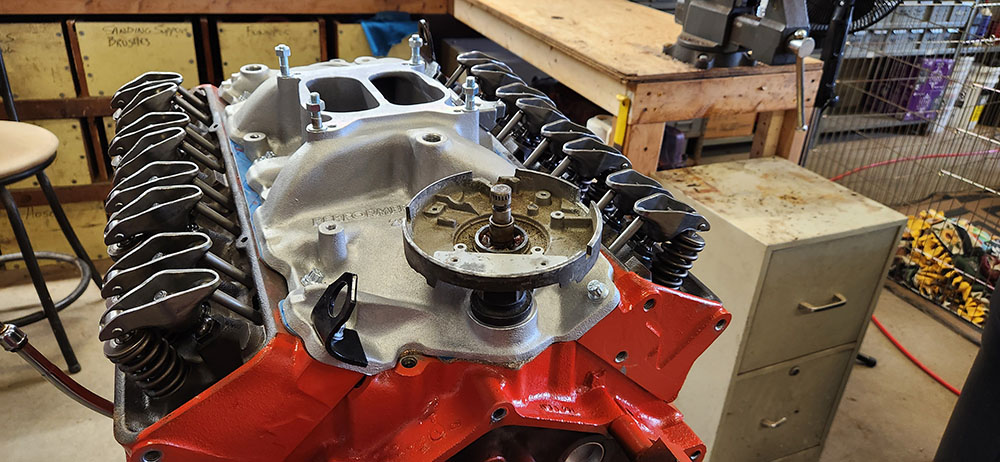

I think I might have talked about this a bit earlier, but without showing it properly. This is plugged in where the engine's distributor goes. That's the gadget that distributes electricity from the alternator to the spark plugs. In action, it's spun by the camshaft via a gear near the bottom of a long shaft that goes through the back of the engine. Near, but not at, because in this type of engine, the very bottom of the shaft has a "tongue" on it that uses its rotation to drive the oil pump (which you will recall is down at the very bottom of the engine).

At some point, someone figured out that if you stuck a properly configured shaft in here without the cam gear on it, and then spun it from above, you could run the oil pump by itself. This is really useful when the engine has been freshly rebuilt, because it means you can pressurize the lubrication system, and thus get oil up to the valve train and whatnot, without needing to turn the engine over dry at high RPM. It solves the chicken-and-egg problem.

Purpose-built oil system priming tools are available, but we made this one by ripping all the electric gubbins off an old distributor, removing the gear so it won't drive the camshaft backward, and then plugging it on in there. When the time comes--hopefully quite soon!--to prime the lubrication system, we'll just chuck the biggest drill we have onto the top of the shaft and let 'er rip.

--G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam.

RE: Project 350 Session 11

RE: Project 350 Session 11 RE: Project 350 Session 11

RE: Project 350 Session 11

RE: Project 350 Session 11

RE: Project 350 Session 11 RE: Project 350 Session 11

RE: Project 350 Session 11

RE: Project 350 Session 11

RE: Project 350 Session 11

Printer-friendly copy

Printer-friendly copy