Originally posted April 13, 2017

One of the common threads of firearms development during the Second World War is that most of the combatants that used submachine guns introduced simpler, cheaper, easier-to-manufacture new models during the war. Sometimes these were simplified variants of existing types, as with the Japanese Type 100 and Type 100 Simplified (known to Allied troops as the 100/40 and 100/44, respectively), or the British Lanchester (itself a more or less shameless copy of the WWI German MP18), which evolved into the Sten. Others, however, were new designs entirely. The US Army, for instance, sought to replace the heavy, complicated, expensive Thompson gun with the M3 "grease gun". The Germans switched from the MP34 to the MP40. And the Soviet Union replaced the PPD-40 with the PPSh-41, and then looked to replace that with this:

The PPS-43. (Sort of. We'll come back to that.)

Stepping back for a moment, you've probably seen the PPSh-41 in war movies. It was one of the more recognizable Soviet firearms before the AK-47, with its drum magazine and distinctive barrel shroud.

(This isn't a real one, alas. It's a non-firing replica from the nice folks at International Military Antiques.)

Under the standard Soviet naming system for small arms, the PPSh is called that because it's a submachine gun (pistolet-pulemyot, literally "pistol machine gun") designed by Georgi Shpagin ("Sh", Ш, being one letter in the Cyrillic alphabet). It was the first Soviet SMG to use stampings instead of milled forgings for its major parts, which made it cheaper and easier to produce than the PPD-40 that preceded it. It was extremely popular with the soldiers who used it, partly for its sturdy reliability and partly for its absurd rate of fire—something in the neighborhood of a thousand rounds per minute.

It appears, however, that the Red Army's ordnance officers weren't as enamored of that quality of the PPSh. One of the requirements in the specification they issued in 1942 for its successor was that the new gun should be simpler to manufacture and have a lower, more controllable rate of fire, while maintaining comparable accuracy and ballistic performance. The latter was easy enough for Sudayev to maintain: he simply used the same cartridge (7.62×25mm Tokarev) out of a barrel of similar length (~270 mm). The rest he accomplished by ruthlessly eliminating machining operations from the design of the gun until there remained only the ones for the parts he could find no other way of making.

The result was adopted as the PPS-42, then improved and simplified even further to produce the final, definitive version, the PPS-43. With its cyclic rate of fire (that is, the theoretical rate it would achieve if it had an infinite ammunition supply and heat was not a factor) reduced to around 600 rounds per minute, it was less of a firehose to handle than the PPSh, if arguably less intimidating, and yet still cheaper to make. Although, in the grand Soviet style, they then didn't stop making the PPSh. It actually remained in production longer than its replacement (PPS production ended in 1946, PPSh production in 1947). They also made far more of the more expensive gun (~6 million PPShes to around a third as many PPSes), because reasons.

At any rate, with two million made by the time Soviet production ceased, and a handful of fraternal socialist copies (the Chinese Type 54 and Polish PPS wz. 43), the PPS was by no means a failed design. Indeed, it received the sincerest form of flattery a military weapon can receive when examples captured by the Finns during the Continuation War were used as the basis for their 9mm KP m/44 (this is a bit amusing in that some features of the gun the PPS was meant to replace, the PPSh, were blatantly knocked off the preceding Suomi KP/-31). The Finnish version, in turn, would go on to be copied by the Spanish and then used in that form by the West German border police, which is... odd, but there you are.

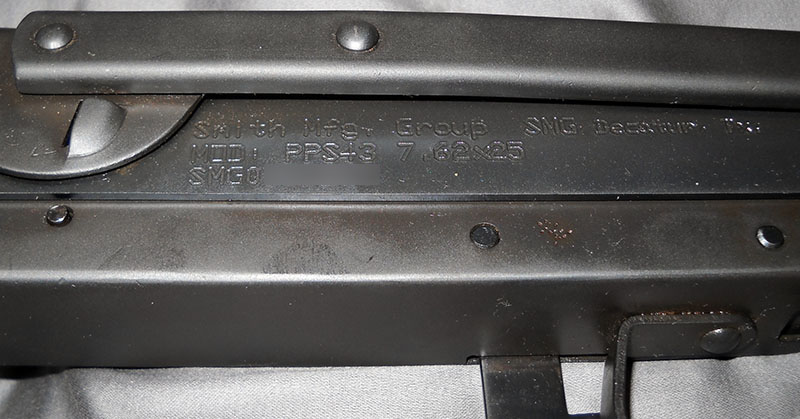

It's the Polish version, first manufactured under license in 1948, that we ought to be concerned with today, because the PPS you see pictured above is partly one of theirs. A lot of Polish PPS-43s were decommissioned some years back and sold off in the US as parts kits, some of which found their way to a small machine shop in Texas called Smith Manufacturing Group.

SMG (I'm guessing the initials aren't a coincidence) is better-known nowadays for their extremely ambitious, and (a bit surprisingly, given the usual way these things work out) evidently successful, effort to put a semi-auto version of the World War II German Fallschirmjägergewehr 42 into production. Habitués of Forgotten Weapons-slash-InRange TV will remember the SMG Fg 42 prototype turning up in a few of the latter's match videos.¹

SMG's Fg 42 repro looks mighty awesome, but this isn't about those. If anybody wants to drop 5 large in the tip jar I will absolutely get one and review it ASAP, but right now we're going to talk about one of the shop's other projects. Before getting obsessed with the Fg 42 project, one of the things they used to do was build PPS-43s to order for people. They stopped doing that when the Fg 42 ate all of their production capacity, but they still had a few sets of the parts lying around, and a note on their website indicated that they'd be willing to take a few days and put one together for anyone who still wanted one.

Well, I've never had a gun that was expressly built to my order before, so that sounded pretty neat to me. I sent them a check a couple months ago. As I type this bit right here, FedEx is informing me that my PPS will be arriving at my local canoes-n-guns shop tomorrow, gods willing and the crick don't rise. (And it might, we're supposed to be getting somewhere between six inches and a foot of snow tomorrow. Yes, in April. Maine! As the big sign on I-95 in Kittery will assure you, it's the way life should be.)

Back at it the following day, and as luck would have it, the lousy weather held off until later in the day, so my delivery proceeded without a hitch, and here it is!

I believe this particular PPS has a few Polish parts in it, but the bulk of it was built domestically by the shop that made it. For a little while a few years ago, the Polish arsenal at Radom built a semiautomatic version of their own, the PPS-43C, that was imported by a company in the States; I've seen pictures online of their conversion, and it isn't quite as elegant as SMG's. Radom actually converted original full-auto receivers for their semi-auto bolt and trigger array, which led to some peculiar features (including a strange double-layered area at the base of the barrel). SMG's receiver is new-made for the job and as a result, I would assume, cannot accept original full-auto parts.

I blurred it for the usual vaguely-tinfoil-hat reason, but I would just like to note that this is the only gun I have with a serial number that has only three significant digits in it. :)

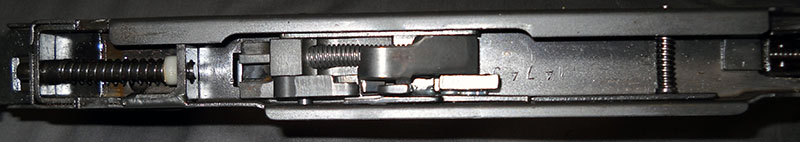

As it happens, converting a PPS-43 into a legal semiautomatic poses a couple of different challenges. The biggest and most obvious is that in its original form, the Sudayev submachine gun uses a classic open-bolt system. In order to make it into a seimauto that the ATF will be OK with, much more than the trigger needs to be changed. It also has to be converted so that it fires from a closed bolt. That, in turn, means that the fixed firing pin must be replaced with an articulated one. That calls for significant machining of the bolt; overall, the conversion is not a trivial job.

Let's take a look at how they did it!

On the plus side, getting at the inner workings of a PPS is super-easy. There are no screws or wedges or even pins. You just press the spring-loaded bit at the back and the receiver hinges open.

Looking up into the upper, we can see the channel the bolt runs in, the recoil spring, and the underside of the bolt.

I don't know what the number on the underside of the bolt handle is—possibly the serial number of the original Polish "donor gun". Apart from modifications to the bolt, this is all pretty much as it would be in a "real" PPS.

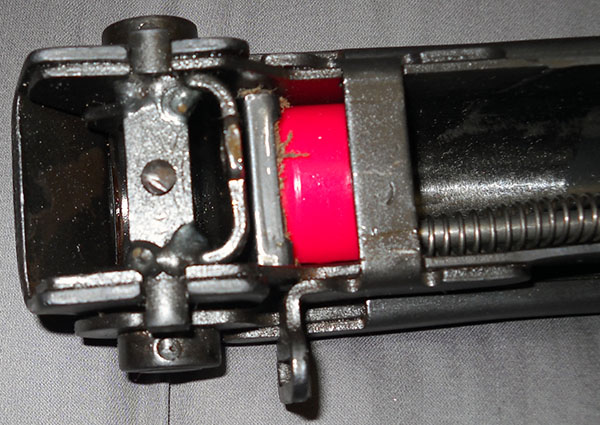

In the lower, on the other hand, it's a completely different animal.

Where the original Soviet lower would contain only the dirt-simple open-bolt, full-auto-only subgun trigger group Sudayev designed, this one has been fitted with a more conventional single-action semiautomatic fire control system. In the photo above, the hammer is cocked; letting it down (which in this case is actually up) makes it much more obvious.

Notice the quite robust hammer spring. (Soviet military cartridges like 7.62 Tokarev are notorious for their hard primers.) The other spring behind it is the one for the disassembly switch; barely visible in front of it (at the far right) is the one for the safety, which we'll get to in a minute.

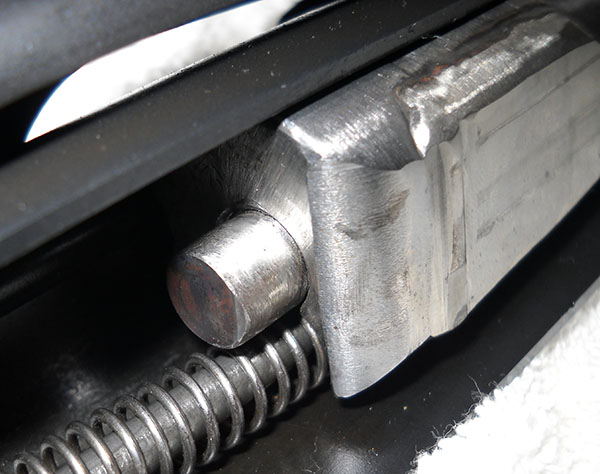

The bolt and recoil spring can be removed for cleaning, but I didn't bother; we can see enough with it left in place. The critical modification is this one:

That's the back end of a spring-loaded firing pin, which was necessary for the switch to a closed bolt. (And it is really spring-loaded, unlike the free-floating one in e.g. the SKS.)

A bit unfortunately, the only part remaining from the original PPS control system is the safety control.

I say unfortunately because it is terrible. It's a nice big control, I'll say that much for it, but it's uncomfortable, it's awkward, it's difficult to put on (you have to press that tiny spring-loaded button a bit behind the magazine well to free it, then slide it backward) and, at least in this particular example, it's very easy to jam in the "on" position. (The instructions I received say "simply move forward to disengage," which gives me a bit of a chuckle as I partially disassemble the gun to turn it off.) It's a simple enough mechanism, but either something is slightly amiss with mine or I'm managing to do it wrong.

Even if it worked perfectly as described, though, it'd still be pretty bad, just because of the control's terrible ergonomics. In fact ergonomics, it has to be said, are not the PPS's strong suit generally. Since it's a simple blowback action in a pretty potent cartridge, it has very stiff springs, and that bolt handle is not what you would call contoured for comfort. Moreover, because it was designed to be made almost exclusively of stampings, it has a lot of hard corners and uncomfortable edges on it. The only exterior part that isn't stamped steel is the pistol grip, which is basically a black plastic (or possibly Bakelite) box. It's not great either, but it's better on the hand than the metal parts. There's no hand guard up front at all, either, which leaves one with an awkward decision to make as to where to put that hand.

It'd help to be able to use the folding stock, as uncomfortable as that would inevitably be, but the one on this particular PPS doesn't work. In order to avoid classification as a short-barrelled rifle under the National Firearms Act, this one had to be built and papered as a "pistol", and that means it can't have a working shoulder stock.

Mind you, that folding stock you can see on top of the reciever is real, not just a cosmetic mockup. It is, however, welded in place.

There's another small tack weld on the structure above that crosspin, which I couldn't get a good camera angle on. The spring is still in there, so I think if one were to get a machinist to cut those welds and polish everything the stock could be restored to working order, but right now it's disabled.

Of course, making that repair would put one in violation of the NFA. SMG's website indicates that they used to make a non-NFA "carbine" version of this, with a 16-inch barrel for compliance purposes, but they were out of those barrels long before I ordered mine, so it wasn't an option. I could have had them build this one as an SBR, but I didn't feel like waiting around for a year. I think it's possible to register an SBR you haven't made yet (as a "manufacturer"), then proceed with the repair once the tax stamp comes, but I'm not certain of that. Might be worth looking into one of these days, because I'm pretty sure I know someone who knows someone who could fix that stock.

Without it, though, what you have here is a big, unwieldy, awkward, but legally compliant so-called-pistol. Sound familiar? Yup, it's the Um, What The?'s grandfather. :)

Also visible in the shot above: that red plastic thing is an impact buffer for the bolt, which otherwise would tend to slam violently into the back of the receiver on each shot. In the originals, that was probably either rubber or some kind of dense fiber. The plastic will presumably age more gracefully than those materials, though it will be in for a lot less of a beating in this gun than the ones in the full-auto models had to endure.

Lest I sound like I'm too down on the PPS, let me just note that I understand why its ergonomics are terrible, and why that didn't particularly matter at the time. One must always keep the designers' intent in mind when judging these things. In that vein, one of the undeniable advantages of the PPS-43's design is that, unlike the PPSh-41, it uses a double-stack, double-feed magazine, something that carries over unmodified into the closed-bolt semi-auto version.

The PPSh's distinctive drum magazine is single-feed, and so the box magazines you almost never see in photos, but which were available for it, were double-stack single-feed. The PPS's are simpler to make and (theoretically) more reliable. They do make the machining of the bolt slightly more complex, but since the bolt is one of only two parts of the gun that actually has to be machined, adding an operation or two there to save complexity on the stampings and internals for the magazine was probably worth it. At least we can reasonably assume that Sudayev thought so.

As a historical footnote, the PPS-43's designer was quite a young man, particularly by Soviet establishment standards; Sudayev was all of 30 when he developed the original model. Toward the end of the war, he started working on an assault rifle to use the 7.62x39mm M43 cartridge. The first version, tested in late 1944 (and so designated the AS-44), was too heavy, but otherwise seemed promising, so the Soviet equivalent of the Ordnance Department sent him off to develop a second version. The prototype for this one was much lighter, but initially didn't work very well.

Sudayev probably could have fixed that in time for the second round of trials in 1946, except that—aged just 33—he died of an unspecified illness² before they took place. As a result, the Kalashnikov offering from Izhevsk ended up being adopted as the standard Soviet rifle the following year, and the rest, as they say, is history.

Still, if Sudayev didn't leave as great a legacy as he might've, he did at least leave something of one, and part of it is this: the SMG PPS-43, my first ever bespoke gun. Awkward, uncomfortable, ludicrously impractical... but very, very cool.

--G.

¹ They are not to be confused with HMG, Hill & Mac Gunworks, who are putting a semiauto StG 44 into production of late. I guess it's a good time to be a WWII German rifle aficionado with a lot of disposable cash at the moment. :)

² And when I say "unspecified" I mean it, no account I've seen has had any mention of what it was. Which, perversely, probably indicates it was an actual illness and not Stalinitis (also known as Sudden Bullet Syndrome); if it had been the latter, surely some modern chronicler would've remarked on it by now.