Originally posted June 10, 2017

In the decades immediately following the Great War, as the prospects for its "War to End All Wars" moniker being true looked less and less promising, many countries looked into developing or procuring new armaments, including handguns. We've already seen some of the results: The German Army, which—let's be honest—knew a war was coming because its leadership intended to start one, adopted the Walther P38 to replace the complicated and expensive Luger. The French Army toyed with the idea of adopting the latest 9mm pistol from neighboring Belgium, FN's GP-35 (better known in the English-speaking world as the Browning Hi-Power), though they hadn't bothered when the war started (and as it turned out, wouldn't after it was over). In England, the British Army stole adopted the Enfield No. 2.

In Finland, the concerns were slightly different. The Finns weren't terribly preoccupied with the prospect of another Europe-wide war. Their concern was much more local. They had only wrested their independence from the dying Russian Empire in 1917, at the cost of a brief but violent civil war against forces backed by the newborn Soviet Union. With the power that had backed the victorious anti-Bolshevik faction—the German Empire—demolished in the aftermath of the Great War, Finland's independence was precarious, and the Finns knew it. The Bolsheviks, once they were done consolidating power in the new USSR, had designs on bringing Finland back into the Russian fold, and they weren't being secretive about it.

This may go some way toward explaining why a country as small as Finland developed and produced its own firearms rather than buying them in from outside. Fortunately, despite being small and not what you would call an industrial powerhouse, Finland did have an indigenous firearms designer of no small ability: a man named Aimo Lahti. Though he had only an elementary-school formal education, Lahti was machinist and gunsmith enough to be made a master armorer in the Finnish Army in 1921, at the age of 25. The following year he designed the Suomi KP/-31 submachine gun, which remained in production for more than 20 years and ultimately became one of the signature Finnish weapons of the Winter War (and which the Soviet PPSh-41 eerily resembles in many respects). He also developed machine guns, at least one of the several Finnish-improved versions of the Russian Mosin-Nagant rifle, and the L-39, a 20mm(!) anti-tank rifle—one of the last and most physically impressive of that already-obsolescent breed.

In between the machine guns and the L-39, Lahti made another contribution to Finnish small arms independence (and, by extension, Finnish independence generally) by developing a pistol specifically adapted to the local conditions. This was called, after the year of its adoption, the L-35.

At first glance, the L-35 looks a bit like a Luger, but even a cursory examination will reveal that beyond the general physical layout—rectangular main body, exposed barrel, sharply raked grip angle—it's a very different animal. Mechanically, the L-35 more closely resembles a Nambu, although that too is only a limited resemblance. Let's dig in, because there are a lot of interesting details about this beast.

First of all, since you won't be able to tell from that side of the screen, it's very heavy. It's a large pistol, a full-size service sidearm, but even so, it's heavier than it looks like it should be. A loaded L-35 weighs more than two and three-quarter pounds, where a comparably sized Luger clocks in at just under two and an alloy-framed Walther P38 around one and three-quarters (all of them holding the same amount of the same ammunition, eight rounds of 9×19mm Parabellum). This is a pistol made by taking three big ol' slabs of steel—one for the frame, one for the barrel/upper, and one for the bolt—and then not cutting off as much as you might think.

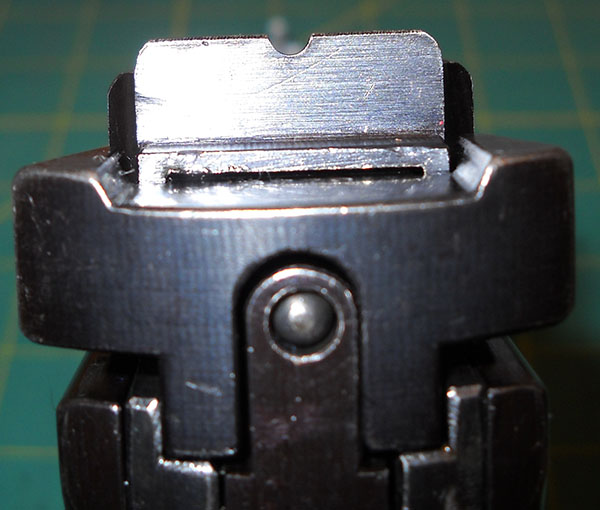

Locking the action open on an empty magazine reveals the kinda-Nambu-like construction of the L-35. Rather than a Luger's toggle action, it has a bolt (in this case rectangular in cross-section, rather than round like a Nambu's) that reciprocates within an upper receiver that is integrated with the barrel. In the photo above you can also see that it's a short-recoil system; the barrel and upper have moved backward a few millimeters before the bolt unlocked and continued the rest of the way back by itself. In operation, this would (as usual) extract and eject the empty cartridge.

The diamond marking on the grip panel, by the way, is the initials of the Finnish Valtion Kivääritehdas ("State Rifle Factory)", where they were made. After the war, VKT became part of a larger government-owned conglomerate, Valtion Metallitehtaat ("State Metal Works"), which later had its name shortened to the internationally-catchier "Valmet" (what practically everyone had always called it anyway).¹

(Also clearly visible in the above shot is the pistol's large, rather-Luger-style safety lever, positioned for the right-handed shooter's thumb. Back is safe, forward is fire.)

At this point I should digress from my digression and confess that this is not entirely a Lahti L-35. Much of it is, but in reality, this specific example is a bit of a hybrid. You see, a few years after VKT started building L-35s for the Finnish armed forces, neighboring Sweden was looking for a new pistol to replace the aging Browning .32 automatics they'd been using. They originally intended to go with the Walther P38, but then Germany went and started a world war and decided to keep all the P38 production for itself, leaving the Swedes looking around for Plan B. As it happened, the Finns had a nice-looking pistol just coming into widespread distribution with their army at the time, and unlike the P38, it was even already optimized for operations in the frozen north.

VKT wasn't interested in supplying production for the Swedish forces—they had all they could do just to meet the orders from other parts of the Finnish government, since Finland had also just gone to war (in their case, with the Soviet Union)—but they were willing to license the design if the Swedes had someone locally who could build them. After some fumbling around with another company that went bust just as the deal was made, the Swedes came up with one, a company which rejoiced in the name Husqvarna Vapenfabriks AB ("Husqvarna Weapon Factory, Inc.," more or less).²

The Husqvarna version of the Lahti pistol incorporated a few simplifications, most notably the omission of the L-35's loaded chamber indicator (which in the earliest-model L-35s was a large and prominent feature on top of the receiver); it was adopted in 1940 and duly named the m/40. Despite the changes to the design (which mainly had to do with making it easier to manufacture), the parts are still largely interchangeable between the two pistols. We can see that clearly if we turn this particular example over...

... because it's made from parts of both. What we have here is a VKT L-35's frame and bolt (the serial numbers still match) fitted with a barrel/upper from a Husqvarna m/40. Exactly when or why this was done, there's no telling now. I'm guessing the "why" was because the original upper cracked at some point. Early-production L-35s were a bit notorious for that, while, conversely, early m/40s were equally infamous for frame failures. In both cases this appears to have been because the standard 9mm Parabellum ammunition issued by both armies was optimized for submachine guns, and thus too hot to be entirely safe in handguns. (Some sources also include some tutting about the state of Swedish metallurgy, but seriously? Sweden is, and was then, renowned for the quality of its local steel. Not sure I buy that explanation. Then again, it was wartime, and the Germans were sort of taking most of Sweden's steel production. So who really knows.)

Regardless, whether this VKT frame's original upper broke, or the m/40 donor's lower frame broke, or both, we can't know now. All we can tell is that someone, at some time in the last 70 years, took the frame and bolt from an early-postwar commercial L-35 (and we know it must have been very early postwar, since VKT became Valmet in 1946) and fitted it with the barrel-and-upper from an m/40. This makes it about a 60/40 Finnish-Swedish hybrid, which presumably means it hates its own guts and spends a lot of time sniping at itself in online forums.

Anyway, let's get in there and see a little more about how it works. The L-35 has a takedown lever that will look familiar to Luger and Walther P38 fans:

Once that lever is turned down like that, the upper assembly is free to slide forward off the frame, at which point the bolt and its locking device can be pulled (along with the recoil spring and its guide rod) out of the back of the upper and separated.

The piece at the top of that photo is the locking device, which is a U-shaped bracket that fits into a space in the top of the upper receiver (you can see the slot for it in the upper above, just about lined up with the locking bracket) and slides down around the bolt, holding it in position relative to the upper. Once the upper and bolt have recoiled together through the full distance of the short-recoil system and the bullet has had time to clear the barrel, the locking bracket is cammed upward into that slot in the upper, releasing the bolt to travel the rest of the way back on its own.

This locking system is not very common today, but it would have been familiar to a Scandinavian arms designer in Lahti's time. It was used in a series of early auto pistols designed by a German named Theodor Bergmann, one of which—the Bergmann-Bayard Model 1910—was the standard handgun of the Danish military until 1946. It's a robust system, well-suited for a pistol designed with a fixed barrel, and much less complicated than (for instance) a Luger toggle lock, which makes it well-suited for the needs the L-35 was designed to meet.

The recoil spring rides in a channel in the underside of the bolt and compresses against a lug at the very back of the frame, as seen here with the upper released but not fully dismounted:

I've said a couple of times now that the L-35's design was optimized to function in wintry conditions. Part of that was the sheer mass of the thing, which gives the moving parts a lot of inertia to overcome potentially increased friction forces (from the cold increasing the viscosity of lubricating oil, and the possibility that ice may have gotten into the mechanism). Lahti hedged his bets further in that direction by including a bolt accelerator in the design, which is something that occasionally turns up in rifles but is quite uncommon in handguns.

The accelerator is that half-moon-shaped bit of metal protruding from the bottom of the upper, to the right in the shot above. That is a complete semicircle that hinges on a pin in its center. When the upper moves backward, the accelerator strikes a surface inside the frame and its forced to pivot around that center pin, which translates the lateral motion into an upward-and-back force against the front of the bolt just as the bolt is unlocking from the upper.

Here it is in its fully engaged position. It hasn't moved far, but that's far enough to impart an extra kick to the beginning of the bolt's independent travel, helping it break free of any ice or gummy oil that might be binding it up.

The downside to the bolt accelerator is that if there isn't anything hindering the bolt's rearward progress, the extra kinetic energy the accelerator provides is not really necessary. Part of the Husqvarna version's reputation for unreliability may have come from the fact that between the hot SMG ammunition and the (possibly) poorer-quality construction, the various load-bearing surfaces in the upper and frame weren't strong enough to cope indefinitely with that excess energy. Indeed, I've seen some reports that Husqvarna omitted the accelerator from the m/40, although obviously that is not universally true, since this is an m/40 upper and it has one.

Looking down into the frame (the front is to the left side of this photo), we can see some more details of the pistol's construction. At left is the latch mechanism for the disassembly lever, shown here in its disengaged position; in the middle is the magazine well; behind that, we can see that like a number of other automatics of its day, the L-35 is fired with a hidden hammer.

In the second shot, the disassembly latch has been turned to the upright or locked position, as it would be with the pistol put together, and the hammer has been released into the "fired" position so you can see its extent of travel. As in virtually all hammer-fired semiautomatics, it's shoved back down into the cocked position by the moving parts during the firing cycle.

This particular L-35 came with a Finnish military-style holster that has obviously seen some mileage, as well as a full set of the accessories that would have been issued with it at the time (although this one seems to have been made for commercial sale).

I assume this is a quality inspection or acceptance marking ("Kontrollerat" doesn't really seem to require a lot of translation).

These accessories consist of a tiny wee cleaning rod (it's not a very long barrel, after all) and a magazine loading tool, as well as a spare magazine.

The loading tool is particularly important. Like virtually all auto pistols with this extreme a grip angle, the L-35 has magazines that are practically unloadable by hand, with extremely stiff springs actuated by tiny, thumb-busting buttons attached to the follower. Lugers, Nambus, and Ruger .22s also have this problem, and the L-35 has it in spades. Even with the little collar tool included, the L-35's magazine is diabolically hard to load. (N.B. In the photo above, I'm not entirely sure one is really meant to use the slot in the cleaning rod for the purpose shown, but it does seem to provide a little more mechanical advantage.)

I had trouble with the magazines for this pistol generally, in fact. On my one range outing with it so far, they were very much a limiting factor. One was incredibly stiff and hard to use, I think because there's still some cosmoline gummed into the spring and follower from some long-ago bout of storage. The other one seemed to work OK until I tried to shoot with it, at which point it dispatched only one round and then stopped working. Cycling the pistol's action produced no result. When I removed the magazine, I found that it was still loaded, but the uppermost round was down inside the body of the magazine.

This effectively beached me and ended my range session, because of a curious limitation of the L-35's design that I hadn't noticed until it became a problem, to wit: there is no manual hold-open. The bolt stays open after the last round leaves because the magazine follower, when it reaches its full uppermost position, trips a switch inside the pistol and activates a bolt lock. However, if the magazine isn't empty, but has simply ceased to push rounds upward, there is nothing to trip that switch, and since there is no way to activate it manually, the bolt simply can't be kept open.

This is a problem if you only have two magazines and want to continue shooting, because you can't fit a loaded magazine into the L-35 with the bolt closed. It won't go all the way up. But you can't hold the bolt open except by hand, and that takes two hands, so you'd need a third one to insert the new magazine. Failing that, and not wanting to try complicated "hold open with both hands, bump magazine home on the bench in front of you" nonsense at a commercial range, you're done for the day if that happens. Which it did. I was pretty annoyed, I have to confess.

When I got home I did a little investigating and discovered the source of the problem:

It's hard to see, but the tip of the screwdriver is pointing out a tiny dent in the side of the magazine on the left. This was not sufficient to stop me from loading the magazine with the help of the loading tool, but in practice, it was just enough to hold up the rounds below it and stop the magazine from working.

This is an excellent example, as it happens, of why fixed magazines held on as long as they did in service pistols like the Roth-Krnka and Steyr-Hahn, and in rifles for even longer. Detachable magazines have many advantages—enough that they would eventually become the accepted standard—but they also have one really significant drawback, and that is that they're susceptible to disabling damage while not in the gun. Usually that takes the form of crippling deformation of the feed lips, but, as we see here, there are other things that can befall them too.

Anyway, I've acquired a couple more magazines for my L-35 since then (I think the "new" ones are surplus from the Danish police, who used the Swedish version of the same pistol after the war), so hopefully my next excursion will be a little more successful. It wasn't a total loss, I did get to do some interesting detective work, but I would rather not have paid $15 and driven 150 miles round-trip just for the opportunity to fire 9 rounds of 9mm ammunition and acquire a mildly diverting mystery.

Anyway.

Sights are about what you would expect from a military pistol of the 1930s, not great, but not terrible either. The L-35 was expected to be used mainly in snowy forests, so it doesn't suffer from the delusions of grandeur in re effective ranges that one often sees in military firearms of the pre-Cold War period. Because it's so big and heavy, it's a comfortable pistol to shoot, or at least that was the impression I got in the course of the one magazine I managed to put through it before the aforementioned malfunction stopped me (lucky I happened to start with the magazine that worked). I did have a slight problem with unintentional double taps, though; the trigger reset spring on mine might need replacing. (This is not a "full auto"-type malfunction, it just means the trigger is lighter on follow-up shots than it seems like it should be. Given enough range time I could probably train around it.)

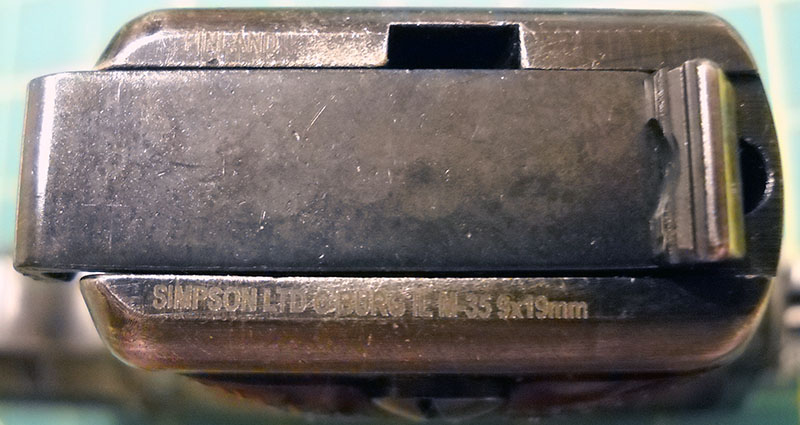

This individual specimen is also a good example of how to do US-government-required import marking right:

Tidy, discreetly placed, legible—the complete opposite of the ones on, for instance, my P38. Unsolicited plug for Simpson Ltd. here, by the way, as I have acquired a number of my C&R firearms from them and the service has always been ace.

(The only thing wrong with these import marks, and I'm not 100% sure it is wrong, is the "M-35" part. It could be an error? Or it could be Simpson winking at the fact that this one is half L-35 and half m/40. :)

As previously noted, the Danish police bought a bunch of m/40s after the war. The Swedish and Finnish armies kept theirs in service into the 1980s. Despite the relatively large number produced, they're fairly rare nowadays, if only because so many were ultimately retired because they wore out or were broken. There was a brief glut of ex-Danish m/40s on the US collector market a few years ago, but that dried up fast, and today they're back to being rare and expensive again. I got a decent deal on this one because it's such an odd non-matching specimen; fortunately, for purposes of this blog, that was actually just about ideal.

--G.

¹ You may have heard of Valmet. I already knew of it, for two reasons: one, they provided a fair bit of the pulp and paper machinery my father was responsible for, as one of Great Northern Paper Company's in-house mechanical engineers, for most of my childhood; and two, they used to manufacture the convertible version of the Saab 900, one of which I very much wish I still had, under contract.

² You may also recognize this name. Today it's a popular brand of chain saws and other such yard care machinery. Husqvarna is also a prominent name in offroad motorcycles, although nowadays that company is Austrian.