|

|

Eyrie Productions, Unlimited

Gryphon

Charter Member

22515 posts |

Mar-18-24, 00:10 AM (EDT) |

|

"Project Impala: Session 12"

| |

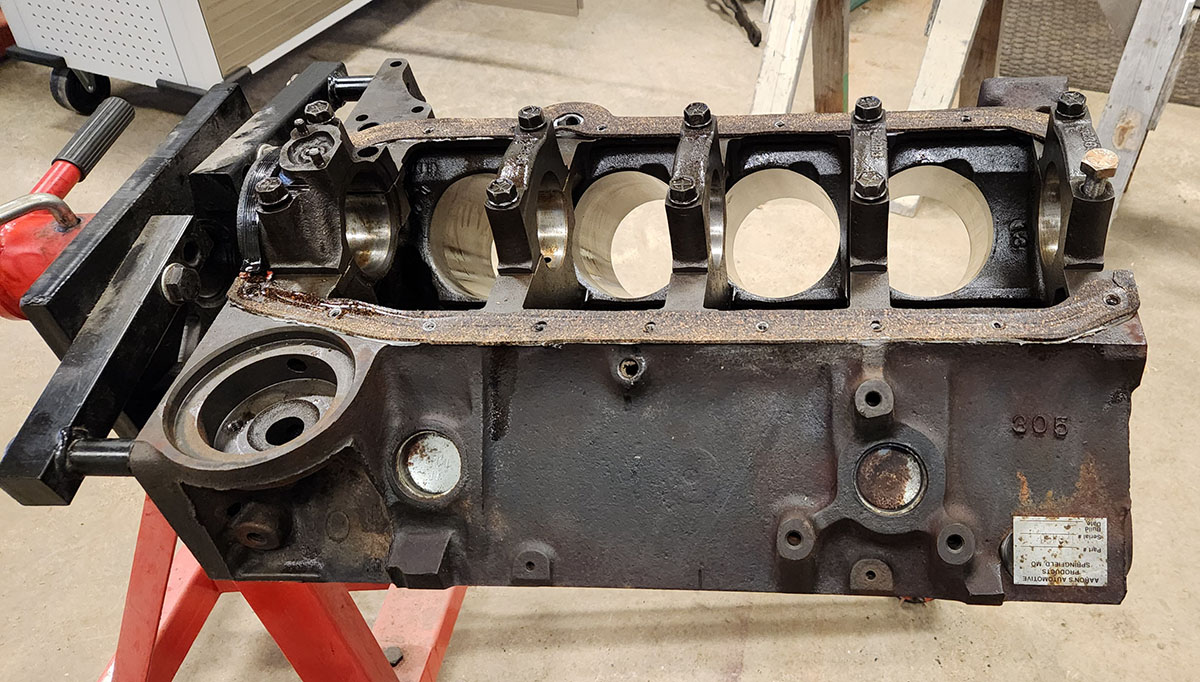

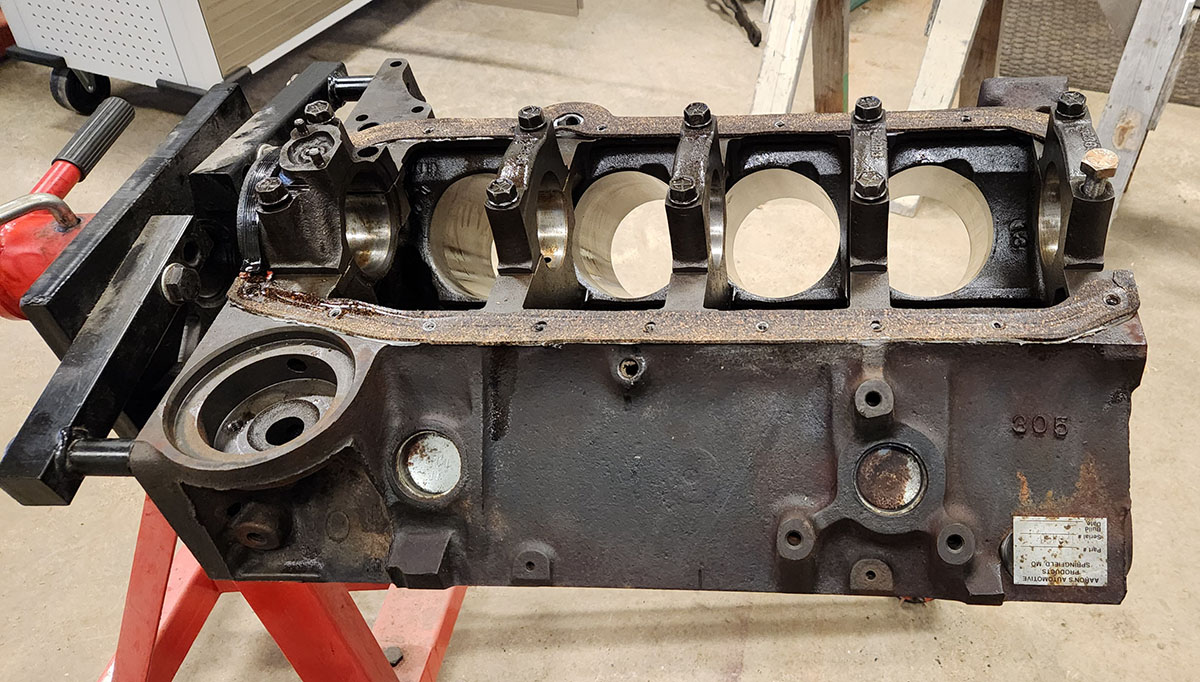

Yes, that's right, today we did actual automotive stuff instead of just more setup on the VAB. Today's mini-project was sort of logistical. We only have one engine stand, and it's had a bare Chevrolet V8 engine block on it for years, waiting to be used as the core of a new engine build for the Impala. However! That block needs to go away to a machine shop to be tested and overhauled before the build can begin, and in the meantime, we've had an '80s 305 with a cracked block kicking around for ages that we wanted to strip for usable parts. So now that we've got the overhead crane set up, we had an easy way to remove the project block from the stand...

(Note the festive pink and white residue from when we checked it for cracks ourselves, long long ago. It's the party block!) ... and replace it with the scrap engine.

The engine stand makes this kind of work a lot easier, because you can rotate the engine on its long axis and work on it upside down, or even on its side if need be. First order of business was to pull off the cylinder heads, which we can probably clean up and use for something else.

As an aside, getting that harmonic balancer off the front of the crankshaft was a big pain in the butt! We broke a puller and had to build another one in a cave with a box of scraps. I didn't have a chance to get many photos of the process itself, since (for once) I was doing most of the wrenching myself, and my hands were too oily to be messing around with my phone. Eventually, though, we got the block fully stripped.

Note the one mismatched bolt on the #1 main bearing cap, far right. That's a little bigger than the others. Years and years ago, Dad bought this engine as a rebuilt unit from Western Auto (which should tell some of you how long ago that was), and it never quite ran right. Eventually he tore it apart and discovered that that particular main bearing bolt had been overtightened and the hole cracked. He tried to fix it by drilling it oversize and putting that bolt in it, but it didn't really work - hence why we're scrapping the block. Still, there's a lot of stuff in there that's perfectly good, low-mileage rebuilt parts, which should have value to someone. Not us, because we're not building a 305, but someone.

So, while the block is going to the scrapper's at some point, the rest of this stuff will probably bring a few bucks if we can figure out where to list it. '80s cars are becoming popular collectibles these days, somehow, so someone out there somewhere is probably building a 305 and would love to have a recently ground crankshaft with a set of clean .030-over main bearings, good pistons with fresh rings, and a mildly spicy cam. Anyway, not the most exciting day's work in terms of the full project, but an important step nonetheless. Also a valuable refresher for me; I know how these engines work from experiences decades ago, a lot of reading, and Car Mechanic Sim, but it's been a long time since I did any work on one with my actual hands. For the curious, the road map for the project engines goes something like this: 1) Have the project block (the pink one above) professionally checked and, if it passes, refurbished by a proper engine machine shop. 2) Use it as the basis for a 327-cubic-inch engine with some fairly mild performance mods. (Unlike the later 305, which is pretty well locked into that displacement, this particular block casting can be used for a few different-size engines depending on the crank and pistons you put in it. We think it was originally built as a 350, back in the day.) 3) Pull the 283-cubic-inch engine that's in the Impala now and replace it with the 327. (It's not the car's original engine anyway, so what the heck.) 4) Overhaul the 283 and put it in Angus, which currently doesn't have any engine in it at all. Transmissions to be determined, though most likely we'll leave the four-speed manual that's currently in the Impala in place and put some sort of automatic in the truck. (Probably a three-speed; the GM automatics with more gears than that didn't come along until after everything became too computerized to stick into a 1966 without a lot of screwing around.) So, there you go. Actual wrenching has happened in the VAB at last. More to come! --G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam. |

|

|

Alert | IP |

Printer-friendly page | Edit |

Reply |

Reply With Quote | Top |

|

|

|

Gryphon

Charter Member

22515 posts |

Mar-19-24, 01:07 AM (EDT) |

|

3. "RE: Project Impala: Session 12"

In response to message #2

| |

>> As an aside, getting that harmonic balancer off the front of the crankshaft was a big pain in the butt! We broke a puller and had to build another one in a cave with a box of scraps.

>

>I'll ask the stupid one. What the heck's a puller? XD It's a tool for pulling things off of shafts and the like. A lot of the time things like crankshaft balancers, steering wheels, and the like are mechanically pressed in place and don't want to come off even if the various retaining fasteners are removed, so you need something that can apply some mechanical advantage to force them off. Pullers come in a few different varieties depending on the situation. There are some that have two or more "fingers" that go behind the item to be pulled off and exert pressure on the central shaft with a large screw; others have a metal plate that's designed to be screwed or bolted onto the face of the pulled item and have the "forcing" screw through the middle. There's also a type that has a slide hammer instead of using screw threads to apply force (these are often used to pull out dents in body panels). In this case we were using one of the "bolted-on plate" type ones, since the crank balancer has threaded holes in it for exactly that purpose, but it was jammed on there so tight that the threads stripped out of the puller plate's center hole before the balancer would budge. The puller in question was pretty cheap and probably just not sturdy enough, so we made one out of an old pulley with a much stouter central hole and it did the job just fine. --G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam. |

|

|

Alert | IP |

Printer-friendly page | Edit |

Reply |

Reply With Quote | Top |

|

|

|

Gryphon

Charter Member

22515 posts |

Apr-23-24, 08:59 PM (EDT) |

|

5. "RE: Project Impala: Session 12"

In response to message #0

| |

Today, in what was effectively a continuation of session 12, we took the Party Block to a machine shop!

Before we took it over, we looked up the block serial number and confirmed that it came from a 1972 four-wheel-drive Chevy pickup, and was originally built as a 350-cubic-inch engine. The truck it came from could have been a half-ton (K-10) or three-quarter-ton (K-20) model; this block has four bolt holes for each crankshaft main bearing cap instead of the usual two, so it probably came from the heavier-duty of the two models, but there's no way of knowing for sure now. That particular block type can be built as a 307, a 327, or a 350 depending on crankshaft and piston rod choices. Dad wants to build it as a 327 for the completely understandable reason that he always wanted one as a teenager but could never afford it, although the guy at the machine shop pointed out that there are a lot more performance parts and whatnot available nowadays for the 350. So, we'll see. Now that it's in their hands, the machine shop will clean and test the block to make sure it's fit for service. If it is (and we have no reason to expect otherwise), they'll bore the cylinders slightly oversize and hone them smooth inside, hone the crankshaft main bearing journals so they're all perfectly cylindrical and aligned with each other, replace the camshaft bearing and freeze plugs, and (if necessary) plane the deck surfaces where the cylinder heads attach so they're as flat as possible. The block will then be ready to have, essentially, a brand new engine built around it. For those who may not know, overboring the cylinders is a standard reconditioning practice for these engines; it removes surface irregularities caused by normal wear in a high-mileage but otherwise undamaged engines and leaves the inside cylinder bores as close to perfectly true and smooth as possible, which makes for the best possible seal with correctly sized pistons and rings and so allows the engine to run as smoothly and efficiently as possible. Ill-fitting pistons allow oil to get into the combustion chambers and exhaust to blow by into the crankcase, neither of which is good. Since this is so commonly done, slightly oversized pistons and rings fitted to the typical range of overbored cylinder sizes are readily available. The most common practice with Chevrolet small-block V8s is to go 0.030 inches over the factory diameter (usually called "30 over", since American machinists like to talk about tiny increments like this in thousandths of an inch). All this is by way of noting that we won't know what size pistons/rings to buy until we've heard from the machinists, but most likely we'll end up going 30 over on our block too. If we build it as a 350, that would make it displace about 355 cubic inches in reality--not enough for any significant performance gain. We'll be making most of our power with our intake and fuel system choices instead. It's worth noting at this point, if I haven't mentioned it before, that we're not looking for massive, pavement-ripping, drag-racing power in this engine anyway. The Impala's going to be driven on the street, when it's driven at all. We just want it to be... brisk. :) So, anyway. The block is, at long last, in the shop. Assuming it passes the tests and can be used at all, they reckon it'll be three to four weeks before we can get it back. In the meantime, we'll be digging around for cylinder heads, pistons and rings (once we find out about the bore), and all that good stuff. Things Are Happening™ at last. :) --G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam. |

|

|

Alert | IP |

Printer-friendly page | Edit |

Reply |

Reply With Quote | Top |

|

|

|

Gryphon

Charter Member

22515 posts |

Jun-03-24, 09:49 PM (EDT) |

|

6. "RE: Project Impala: Session 12"

In response to message #5

| |

Good news from the machine shop! The party block is good and we are GO for the build. The cylinders are being bored .030 over and honed for the specific set of pistons we've specced to go with it, the bearing surfaces are being cleaned and made true to their common centers, and the decks (the surfaces where the cylinder heads go) are being squared to the crankshaft and cut down to exactly 9 inches (from the nominal factory height of 9.025 inches). As an aside, there is a lot of fiddly math to be done when you're building one of these things from a completely bare block. Once you've decided which of the available displacements you're going for, you have to figure out exactly what kind of pistons you want to use, what size bearings you'll need once the places where they go have been refinished, and all that jazz. I'll get into that a little more when I'm actually working on the engine. Also, we're going to be using something called "hypereutectic pistons", which sounds a bit more badass than it really is, but still. --G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam. |

|

|

Alert | IP |

Printer-friendly page | Edit |

Reply |

Reply With Quote | Top |

|

|

|

|

|

|

Gryphon

Charter Member

22515 posts |

Jun-13-24, 09:24 PM (EDT) |

|

8. "RE: Project Impala: Session 12"

In response to message #6

| |

I went to the shop today to help arrange more things in proper storage locations, prep for putting up Yet More Steel Shelves (downstairs this time), and whatnot--important stuff but nothing really notable--but while I was there, Bernie from the engine shop called to report that the Party Block will be finished tomorrow morning! We're planning to go pick it up, and at the same time drop off the crankshaft and cylinder heads we're going to use for the build, so they can be cleaned up, have the relevant bits honed and/or polished, and so forth by a professional. Meanwhile, we're plotting ways of installing the new pistons (which we'll be picking up along with the block) on some connecting rods we have without the benefit of the $1,500 tool normally used for this purpose. This could be cool! Or I could ruin a $300 set of pistons. It could go either way, really. I almost feel like I should be vlogging this. Almost. Surely "aging MS boy with failing eyesight and a dominant hand that can't feel textures attempts to build an engine" is a viable entertainment niche. --G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam. |

|

|

Alert | IP |

Printer-friendly page | Edit |

Reply |

Reply With Quote | Top |

|

|

|

|

Nova Floresca

Member since Sep-13-13

609 posts |

Jun-13-24, 11:03 PM (EDT) |

|

9. "RE: Project Impala: Session 12"

In response to message #8

| |

>without the benefit of the

>$1,500 tool normally used for this purpose. This could be cool! Or I

>could ruin a $300 set of pistons. It could go either way, really. Mathematically, you could ruin a few sets of $300 pistons and still come out ahead, though that's certainly Not Optimal. >I almost feel like I should be vlogging this. Almost. Surely "aging

>MS boy with failing eyesight and a dominant hand that can't feel

>textures attempts to build an engine" is a viable entertainment niche. Considering that a substantial amount of streamers' repertoire boils down to "self-inflicted cruelty", it's not unreasonable. "This is probably a stupid question, but . . ." |

|

|

Alert | IP |

Printer-friendly page | Edit |

Reply |

Reply With Quote | Top |

|

|

|

version 3.3 © 2001

Eyrie Productions,

Unlimited

Benjamin

D. Hutchins

E P U (Colour)

|

RE: Project Impala: Session 12

RE: Project Impala: Session 12 RE: Project Impala: Session 12

RE: Project Impala: Session 12 RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12 RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12

RE: Project Impala: Session 12 RE: Project Impala: Session 12

RE: Project Impala: Session 12 RE: Project Impala: Session 12

RE: Project Impala: Session 12 Printer-friendly copy

Printer-friendly copy