Originally posted May 11, 2017

In today's Gun of the Week, we're going to take a look at a representative of a ubiquitous family of guns that are in no way interesting. Here is a Glock.

This particular example is a Glock 21 in .45 ACP, but it doesn't really matter. They're all basically the same, at least the full-size ones. This one sports a few level-1 weapon mods, which we'll get into in a moment. They don't make it interesting, though, because nothing can. It's a Glock. They're the firearms equivalent of dishwater. You might want to come back next week.

(pause)

Are they gone? OK, now that the casuals have left, let's take a closer look at this, because for all that you can tell instantly that it was styled by an Austrian whose previous experience was in the manufacture of curtain rods, it's actually—dare I say it?—kind of interesting.

Glock pistols are often described by the uninitiated as having been the first polymer-framed handguns on the market, and as possessing both a revolutionary operating system and an equally unprecedented ignition system. None of these things are true. As far as I am aware (and I could be missing something), the earliest pistol with a full plastic frame was the Heckler & Koch VP70, which appeared on the market in—no bonus points for guessing this—1970. The operating system in the full-size Glocks is a Browning tilting-barrel short-recoil action, nothing revolutionary there (although Glock's implementation of same is interesting). We've previously discussed how not-unprecedented the semi-double-action striker-fired system they use is. So what's so interesting about these things?

Well, their history, for a start. I've said before that the history of the company and the product are the most interesting thing about Glocks, and that is for the most part true. That story has been told in much greater detail than I've got time or space for here, particularly as it relates to Glock's penetration of the American market, but the really short version is that Gaston Glock's engineering company had never made a firearm before he decided to develop an entry into the Austrian government's early-1980s military and police pistol trials. The established firearms industry (particularly the well-established Austrian firm of Steyr Mannlicher) had a good laugh at the idea that this small-time curtain rod manufacturer was going to try to build a gun, right up until the point where the Glock 17 swept the competition and relegated Steyr's own entry, the GB, to the footnote sections of firearms history.¹

Exactly how much of the 17 was Gaston Glock's own work is one of those things that will always be mired in controversy (as is virtually always the case with 20th-century firearms closely identified with a single designer). As we'll see when we disassemble this one, there are large parts of it that are definitely not original to him, such as... well, the entire operating system, which functions on principles that were very well-established in 1980. Still, it's undeniably a clever package, though to really explore that we'll need to take it apart.

Fortunately, that's pretty easy. You just need to hold the slide slightly back (to take up tension on the recoil spring), then pull down on those two tiny levers on either side of the frame, which disengages the forward slide stop so that the slide-barrel assembly comes off the front of the gun. From there, the slide, barrel, and recoil spring come apart in a manner that will be instantly familiar to anyone who has ever field-stripped a 1911, a Hi-Power, a CZ 75, or any number of other pistols based on the Browning tilt system.

Yes, that's all looking very familiar. Now that it's apart, though, we can take a closer look inside that plastic frame and see what's really going on. One of the common questions that came up, when these things were first appearing on the market in the early 1980s, was how a plastic pistol frame could withstand the violent forces inflicted on it by normal semiautomatic operations. Glock's PR people would happily (in a dour, Austrian sort of way) roll out figures showing that the polymer they use is stronger than steel, when measured in Certain Ways, but that's only part of the story, and a look down into the frame of a Glock will show you the rest.

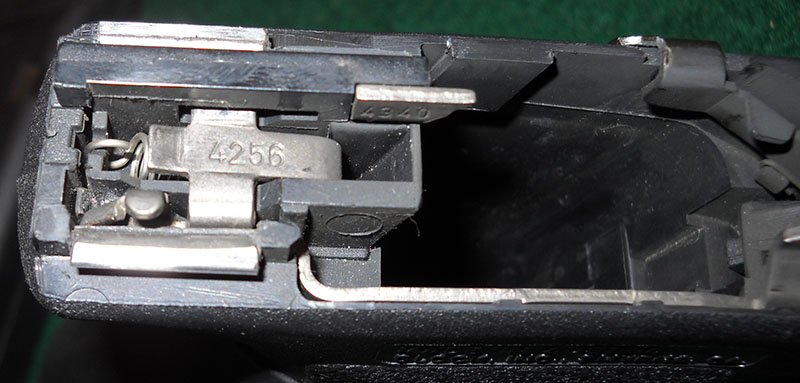

At the right of this photo, you can see the first detail, which is that the frame rails are reinforced with those spring-loaded metal tabs. I haven't seen an engineering memo on this from Glock, but I would surmise that these serve to improve the fit of the frame-slide interface (the spring between the tabs will serve to press them outward slightly, maintaining pressure on the slide rails, for a tighter fit) as well as provide a more durable contact surface. In the middle, that black crosspiece is the forward slide stop (the part that is pressed down by the levers to enable diassembly, and when up, prevents the slide from coming forward past the "in-battery" position). And behind that is the heart of the system: a neatly fitted steel block, which provides the striking surface and the necessary mass to actuate the barrel-unlocking tilt mechanism, stop the slide from going any farther back than it's supposed to, and absorb most of the excess recoil energy for transmission into the rest of the frame, thence the grip, and ultimately the shooter's hand.

This, then, is how the Glock's plastic frame can withstand the forces of operation: it doesn't have to, at least not directly. The surface area of the metal-to-polymer interface there is significantly greater than the area of the actual operating surfaces, so the tremendous point loads involved are spread out into a form the plastic can stand up to without cracking or deforming.

I'm not dissing this, by the way. I think it's pretty ingenious. The slide-to-frame interface in a semiautomatic handgun is always a pretty sensitive place. There's a lot going on there, and even when you're working just with metal, it's easy to get it wrong (viz. the tendency of the early alloy-framed Walther P38s to crack). That Glock's engineers were able to come up with a trick like this that works reliably and is still simple and cost-effective enough to mass-produce is pretty impressive.

While we're in here, let's take a look at the stuff at the rear of the frame.

I'll be honest, I don't know exactly what-all this stuff does (or why it's numbered that way, that isn't the pistol's serial number). That triangular bit sticking up in the top middle (so on the left side of the pistol) is presumably the ejector, and the large numbered part in the center is the interface between the trigger (in the frame) and striker (in the slide) mechanisms, but I don't know precisely how it works. You will note, however, that all the important bits in here are also made of metal.

As, for that matter, are the entire slide and barrel assembly, as we can see from a look up into the slide.

As an aside, I'm not sure why, but for some reason the flash on my camera often makes metal look like it's in apocalyptic condition. It could stand to be scrubbed up a little, but it's not clan-shamingly bad. Hasn't actually been used in about 20 years. Anyway, in this view we can see a couple of points of interest. On the left, at the back of the slide, we can see a few bits of the (mostly enclosed) striker mechanism. This can be dismantled further, but I don't have the tool to do that with, so I didn't mess with it. Basically, though, it works just like the striker system in the Roth-Krnka M.7—the striker is sorta-semi-cocked at the end of the operating cycle, and the trigger has to pull it the rest of the way back before letting it down.

Coupled with the Glock's trigger-within-trigger positive did-you-really-mean-to-do-that safety, this does a pretty good job of minimizing accidental discharges, although it does mean the trigger pull is quite heavy for a semiautomatic. On the other hand, it's always the same, which police departments transitioning from double-action revolvers tend to like; that's one of the reasons why (along with reliability and cost) so many cops carry Glocks these days, although the first generation—the ones that replaced revolvers—are reaching the end of their service lives now, so it'll be interesting to see what PD procurement officers prioritize in the next round of acquisitions.

Also in the shot above, you may notice that one common feature of Browning-lockup semiauto pistols is missing: there are no slots for locking lugs up in there, and indeed no lugs on the barrel.

Instead, the Glock's barrel locks up on that squared-off area at the back, which also provides more metal around the chamber (where the most pressure tolerance is needed). The "step" in the chamber top can be seen clearly from above:

This interfaces directly with the front of the ejection port, keeping the barrel and slide locked together for the first few millimeters of their rearward travel, until the tilting cam on the bottom of the barrel interacts with that metal block inside the frame. This tilts the barrel down and disengages the chamber step from the ejection port, thusly:

Thus separated, the barrel stops there while the slide continues back. Extraction, ejection, new cartridge feed, and so forth. So it is a conventional Browning tilt action, but with a slightly different spin on how the lock-up is achieved.

All of this should neatly illustrate how one of the key pieces of general-press FUD about the Glock product line when it first appeared was nonsense right from the off. Reporters who didn't know anything about guns (or who were pandering to readerships they assumed didn't know anything about guns, if you want to be cynical about it) saw the phrase "polymer construction" and leaped to the fanciful conclusion that these pistols had no metal in them, and, in a further leap, that they would thus be invisible to the security systems in e.g. airports. Apocalyptic scenarios of armed-to-the-teeth ruffians storming airplanes, courthouses, and other ostensibly secure locations immediately followed. Legislators fulminated about how these things would lead directly to the complete collapse of civilization if not banned immediately.

This was, of course, complete silliness. There is a ton² of metal in a Glock. Even the much-vaunted polymer frame has significant metal components that cannot be removed without ruining it. Even if it didn't, the frame itself is useless without the rest of the gun, which is entirely made of steel. (Oh yes, and the magazine, which—as you can tell from the edges of the witness holes in the back, has a metal box inside its plastic casing.) For that matter, although it won't set off a metal detector all by itself, the polymer of the frame is dense enough that it shows up just fine on baggage X-rays.

No, as we have already discussed, the real peril of the Glock's popularization of polymer construction was that it would lead to fashion. But I digress.

This particular G21 has had a few modifications. You will already have noticed the grip enhancement, which has obvious finger grooves and a less-obvious-in-photos palm bulge. This has the side effect of making the grip, already pretty chunky with a double-stack .45 ACP magazine in it, quite fat indeed, only suitable for large hands. (Larger than mine, as it happens, and that's not something you'll see me say very often.) It also has an aftermarket recoil spring—the factory ones don't have that telescoping guide rod. I forget exactly what that was for—I think maybe it's a constant-pressure spring (instead of the usual kind that gets stiffer as it's compressed), though I don't recall what benefit that provides in operation if it's the case.

Its magazines have also been fitted with aftermarket floorplates that increase their capacity by two rounds.

This was a particularly sought-after enhancement in the mid-1990s, when this pistol was new, because at the time, new-production detachable magazines in the US were limited by federal law to a capacity of 10. The Glock 21's standard magazines hold 13 rounds; with these attachments, the "post-ban" 10-rounders could be retrofitted to hold nearly as many. This was at least quasi-legal, mainly because whoever wrote the legislation banning magazines larger than 10 rounds didn't think to include language prohibiting it, and in a pinch it could be defended as a non-permanent modification if you had kept the original parts. Nowadays, at least on a national level, the point is moot, since that federal prohibition elapsed some years back, although a number of states now have their own magazine restriction statutes in place.

So, to summarize: what we have here is one of the most ruthlessly utilitarian designs ever produced. It has no frills; it doesn't even have any places to put frills. It's the box-end wrench of handguns. In a way, it reminds me of that other famous European name in unexciting products, Airbus. When you look at the two remaining builders of large airlines in the world today, the contrast is stark. Boeing, despite the undeniable fact that their present products aren't exciting either, are still hanging resolutely on to the last echoes of their industry's old-timey glamour, giving their products names like "Dreamliner" and trying to pretend that flying commercial still has even the faintest whiff of the adventure and romance it once had. Not Airbus. Their ethos is stamped right on the company. "No romance or adventure here. We make buses that fly. Consider yourself fortunate that you're even allowed to travel at all and stop whining."

Glock is like that. If Gaston had thought of it, he probably would have renamed the company "Gun, GmbH" when the product started taking off in the English-speaking market. Oh, they put on some airs in their marketing, because that's what marketing departments do; it's a sort of compulsion. Hence the persistent use of pompous slogans like "Glock: Perfection". And to be fair, it's not Mr. Glock's fault that his name sounds to English-speakers like the sound you make when a ninja finger-punches you in the trachea.³ If his name was, say, Steinhammer, or Eisenfaust, we'd probably all think they were the coolest company ever.

Because Glocks are among the dullest-looking machines ever conceived by human beings, and because they combine the (not groundbreaking at the time, but still pretty radical) use of polymers in non-pressure-bearing components with well-understood principles of firearms engineering, they don't really get the respect they deserve in a lot of circles. People like me, who enjoy the detail and the meticulous manufacturing of something like a Roth-Krnka or the clean metal elegance of an all-steel Hi-Power, regard them kind of like a particular stripe of superhero comics fans look at Watchmen or The Dark Knight Returns: they're significant and important, but for gods' sake why did everyone else have to start doing exactly the same damn thing?

Still, if you take the view—as I'm sure both Gaston Glock and the Austrian authorities who chose it over the Steyr GB and company did—that the only thing a service pistol must do is serve, you would be hard-pressed to find a purer distillation of that philosophy using the firearms technology of the late 1970s than the Glock 17. And there's something appealing about its ruthless minimalism. It doesn't have any styling at all; in its first-generation form it doesn't even have any markings worth mentioning. Apart from the serial number and required proof marks, there's just the company name and model number, what cartridge the gun is chambered for, where it was made, and (for US models) where the importer is and what they're called. (Glock is one of the many European arms companies that has its own permanent US subsidiary for that.)

Mind you, I still don't particularly like Glocks; certainly I have no pressing urge to go and spend my own money on one. (This one belongs to someone else.) But I respect them, as engineering exercises and as tools. Which I'm sure would be fine with Mr. Glock—because the latter is all he ever intended them to be.

--G.

¹ Like this one. Although, as previously noted, the GB had other reasons for becoming obscure. I'd like to get into greater detail on that one of these days, but the dang things are expensive now.

² Not literally.

³ It's German for "bell", which makes me think of a hypothetical piece of German slang. In some parallel universe, das Glockenspiel (literally "set of bells") must be not only the name of a musical instrument, but also an urban euphemism for the sport of having gunfights with Glock pistols (alternate literal translation, "game of Glocks").