Today's adventure: starting to clean up the firewall and front subframe so we can paint them before we drop in the new engine.First, of course, we went to light up the job area a little better and discovered that none of our standing floodlights actually work, because someone used them while spray painting and got overspray on the bulbs, so now they're all burned out.

But who needs specialized job lamps? We've got an engine crane, some rope, and a spare workbench light...

... what else do you need?

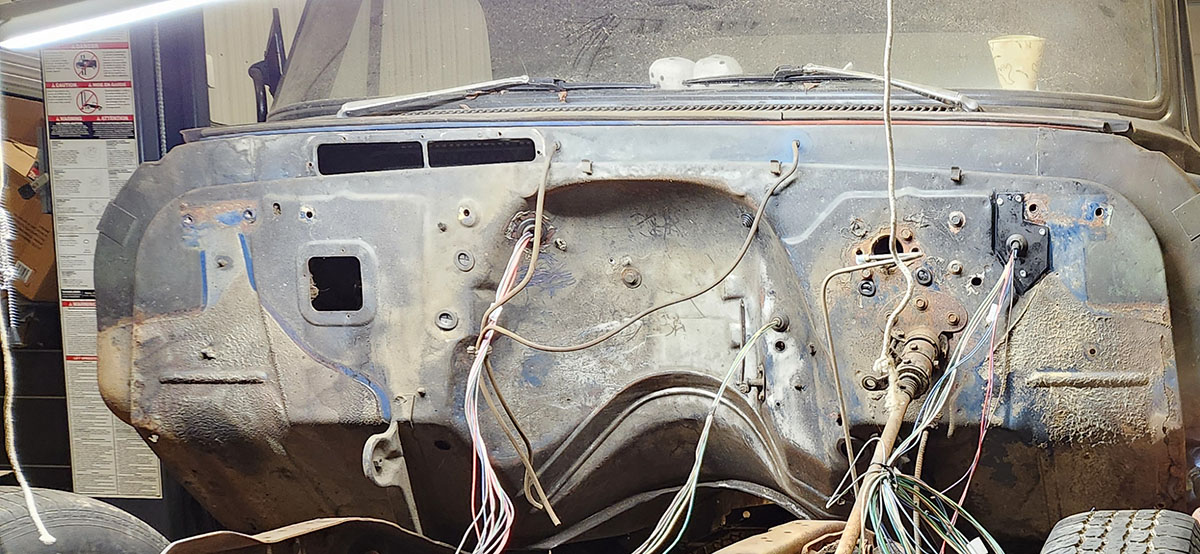

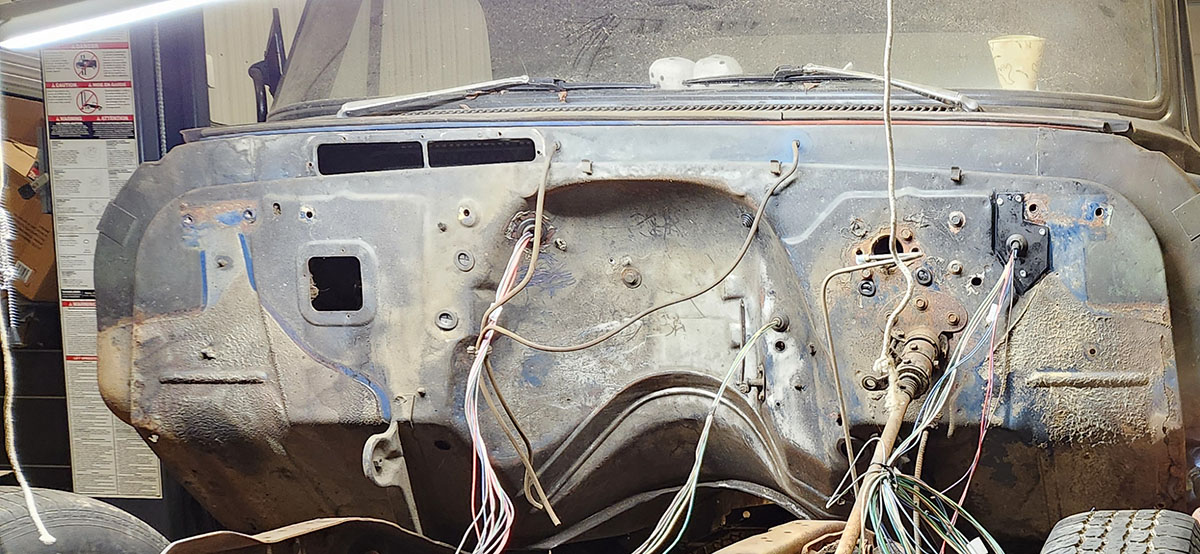

Anyway, as you can see, the firewall could use some cleaning, given that it was probably last cleaned, uh... never.

(Or possibly once, when whoever painted it black did that. It was once the original body color, as you can see in the areas that were covered by the inner fenders.)

Unfortunately, all we had to work with today was an ordinary drill and wire wheel, so it was slow going.

Of note: those holes over on the righthand edge, which... didn't look like they were there when we started. If there was any metal left there under the dirt, it was thinner than tissue paper. We'll need to have a corner piece welded on there or something--but then, we've already seen that there's a lot of seam work that needs to be done in that corner. This is just another manifestation of the same issue.

Also, note that kinda-corrugated-looking stuff in that same vicinity. We thought it was just generational levels of crud from the wheel well, but it's not--it's some kind of long-hardened undercoating material. There's some on the passenger side in the same place. Evidently GM put some sort of sealant in there, possibly to cut down on cabin noise from gravel flying up into the fender wells. Our mere mortal wire wheel wouldn't touch that stuff at all.

We have a die grinder that runs at a much higher speed than the drill and would also be a lot more ergonomic in tight/odd spaces, such as down on the subframe, which we also made a start on today:

Unfortunately, the only wire wheels we could find at any of the local hardware stores were only rated for about 6,000 RPM, while the die grinder runs at circa 25,000. Such things do exist for speeds that high, but can't be bought locally, so that'll have to wait until we can get a shipment in.

We'll have a while to wait for them, though, since Dad has some prior commitments that are probably going to keep him tied up for the next few weeks...

--G.

-><-

Benjamin D. Hutchins, Co-Founder, Editor-in-Chief, & Forum Mod

Eyrie Productions, Unlimited http://www.eyrie-productions.com/

zgryphon at that email service Google has

Ceterum censeo Carthaginem esse delendam.

Session 1

Session 1

RE: Session 1

RE: Session 1

RE: Session 1

RE: Session 1

RE: Session 1

RE: Session 1 Session 2

Session 2

Session 1A

Session 1A

RE: Session 1A

RE: Session 1A RE: Session 1A

RE: Session 1A RE: Session 1A

RE: Session 1A sessons... 3 through 5? ish

sessons... 3 through 5? ish

RE: sessons... 3 through 5? ish

RE: sessons... 3 through 5? ish RE: sessons... 3 through 5? ish

RE: sessons... 3 through 5? ish

dang it

dang it

session 6

session 6

RE: session 6

RE: session 6

RE: session 6

RE: session 6 RE: session 6

RE: session 6

session 7

session 7

RE: session 7

RE: session 7 RE: session 7

RE: session 7 session 8

session 8

Printer-friendly copy

Printer-friendly copy